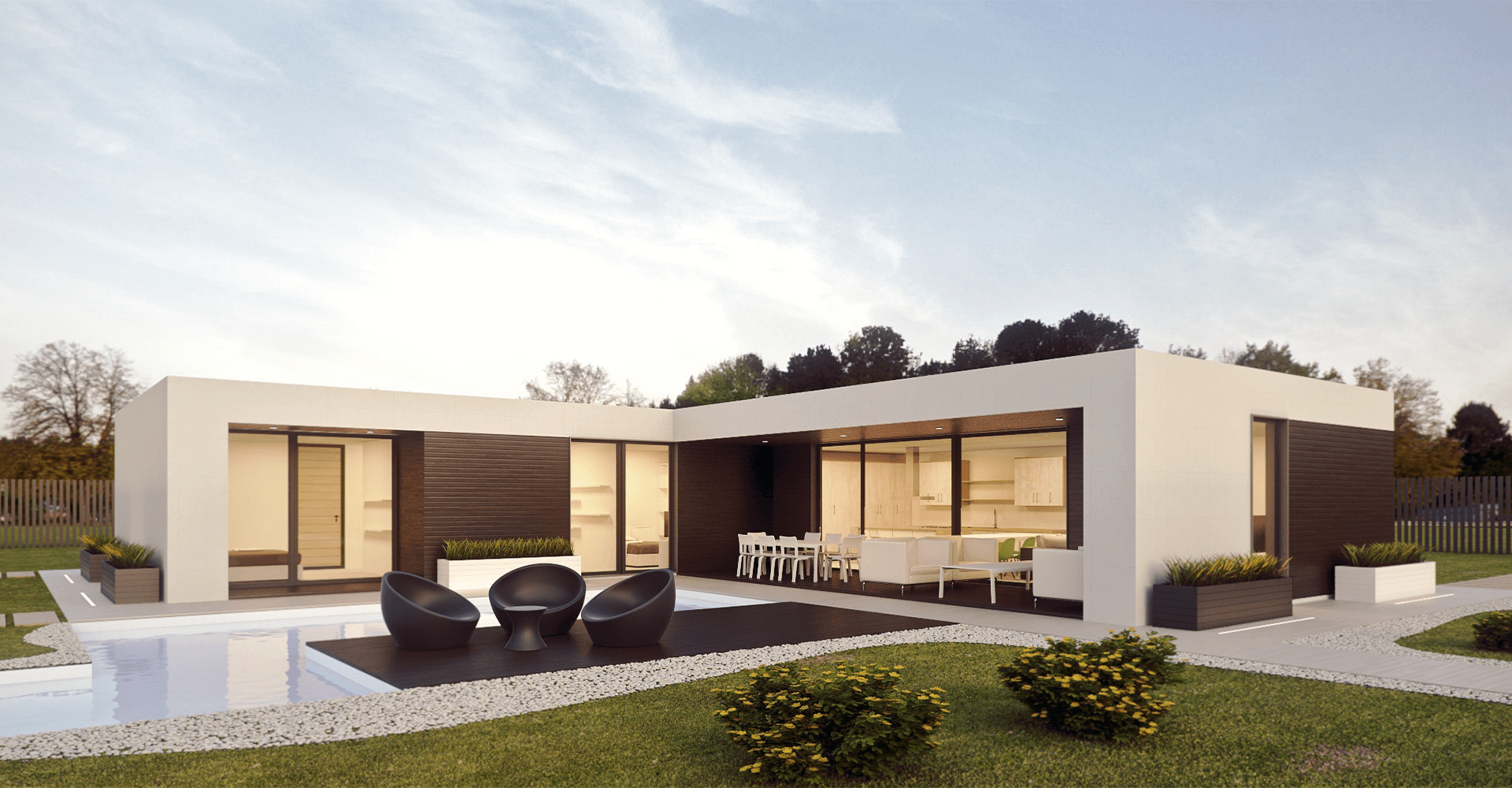

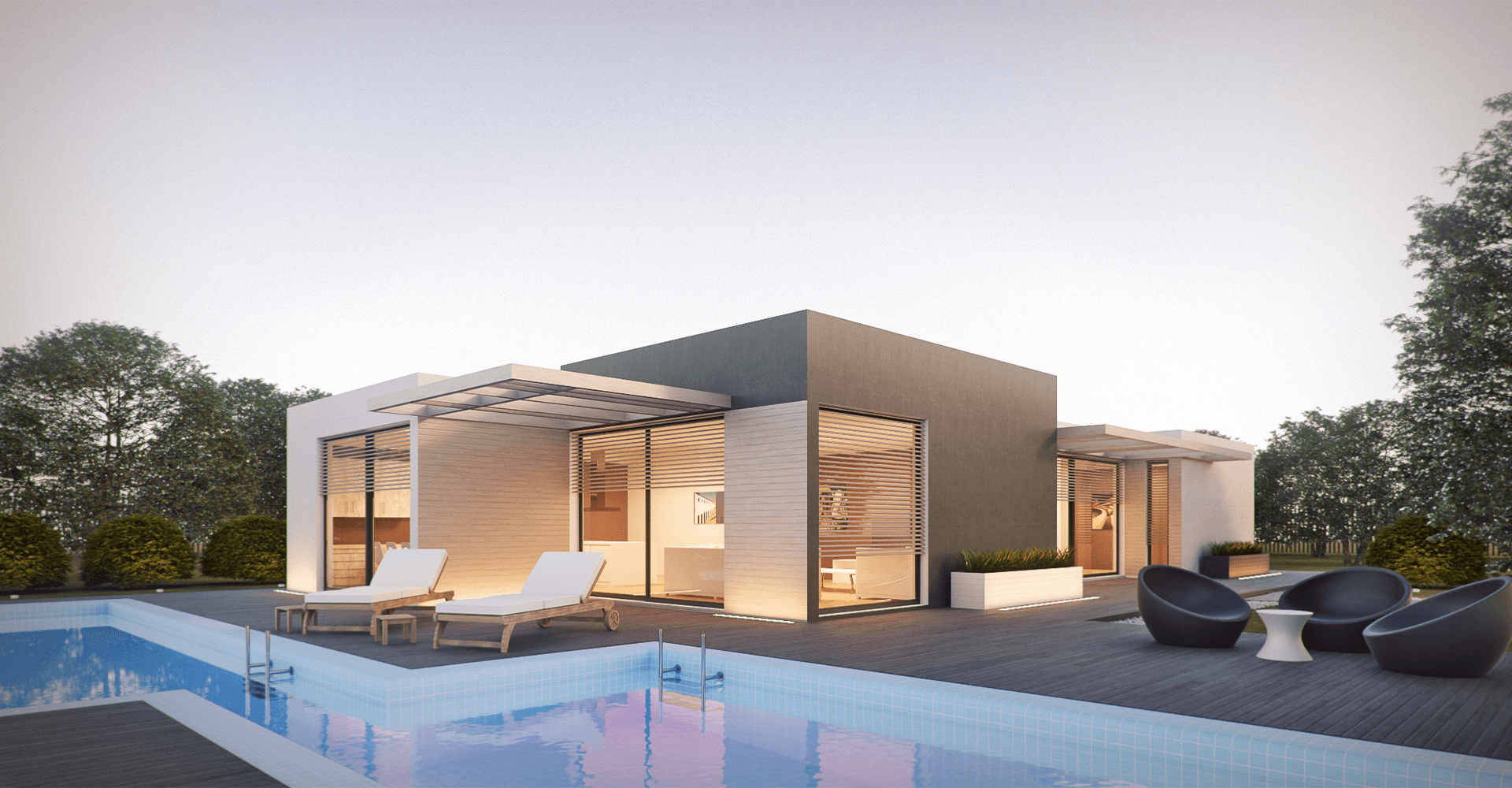

Welcome to ARC Modular.

"Your Future Home Today"

ARC offer a full range of products and services for the Housing and Commercial Markets including Student Accommodation, Health Services, Sports Facilities, Hotels, Retirement residences or Large Scale residential projects. We purpose build for all environments and usage.

Our team consists of high grade specialists in Design, Planning, Conception, Budgeting, Construction, Sales and Marketing. We offer clients a full turnkey service that will provide a wide range of modules that can be suitably configured and flexible to adapt to exactly what the client requires on site, in an ever-changing global market. Arc brings affordable solutions for social housing and first time buyers.

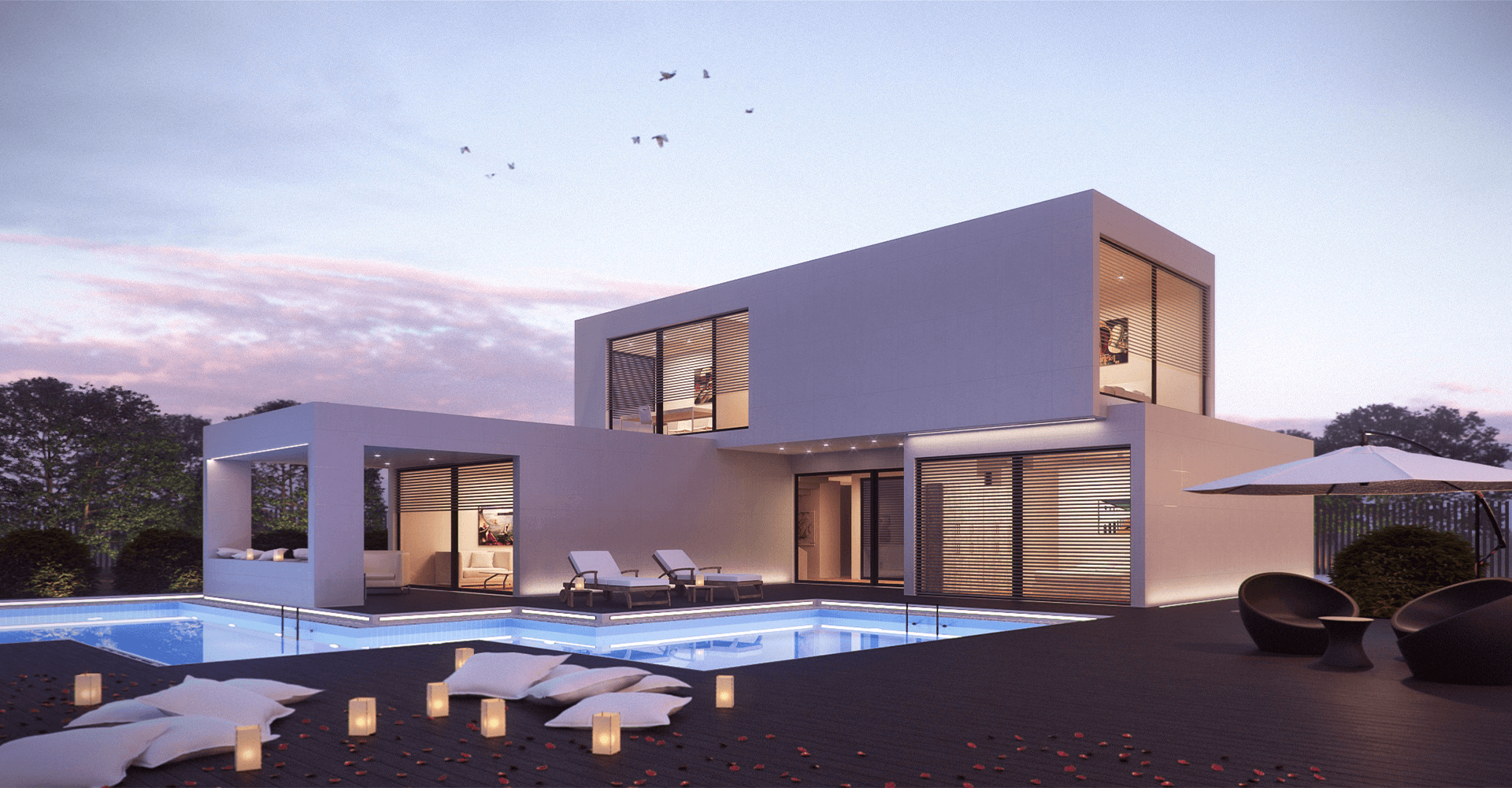

Our construction methodology can be up to 50% faster than traditional construction methods, with delivery to you in as little as 6 to 8 weeks dependant on design.

Our building methods can provide NHBC accreditation, providing the homes are installed by an accredited NHBC contractor on site to ensure criteria is met for Insurance and Mortgages.

Advantages working with ARC.

Each of ARC's partners have vast experience in the field of Offsite Rapid Construction. With the production capacity and the capability to supply to large scale developments, speed and the exemplary quality of the product we are well positioned to deliver to the growing demands of the market. We offer reliability, commitment, experience and efficiency. We make your projects happen.

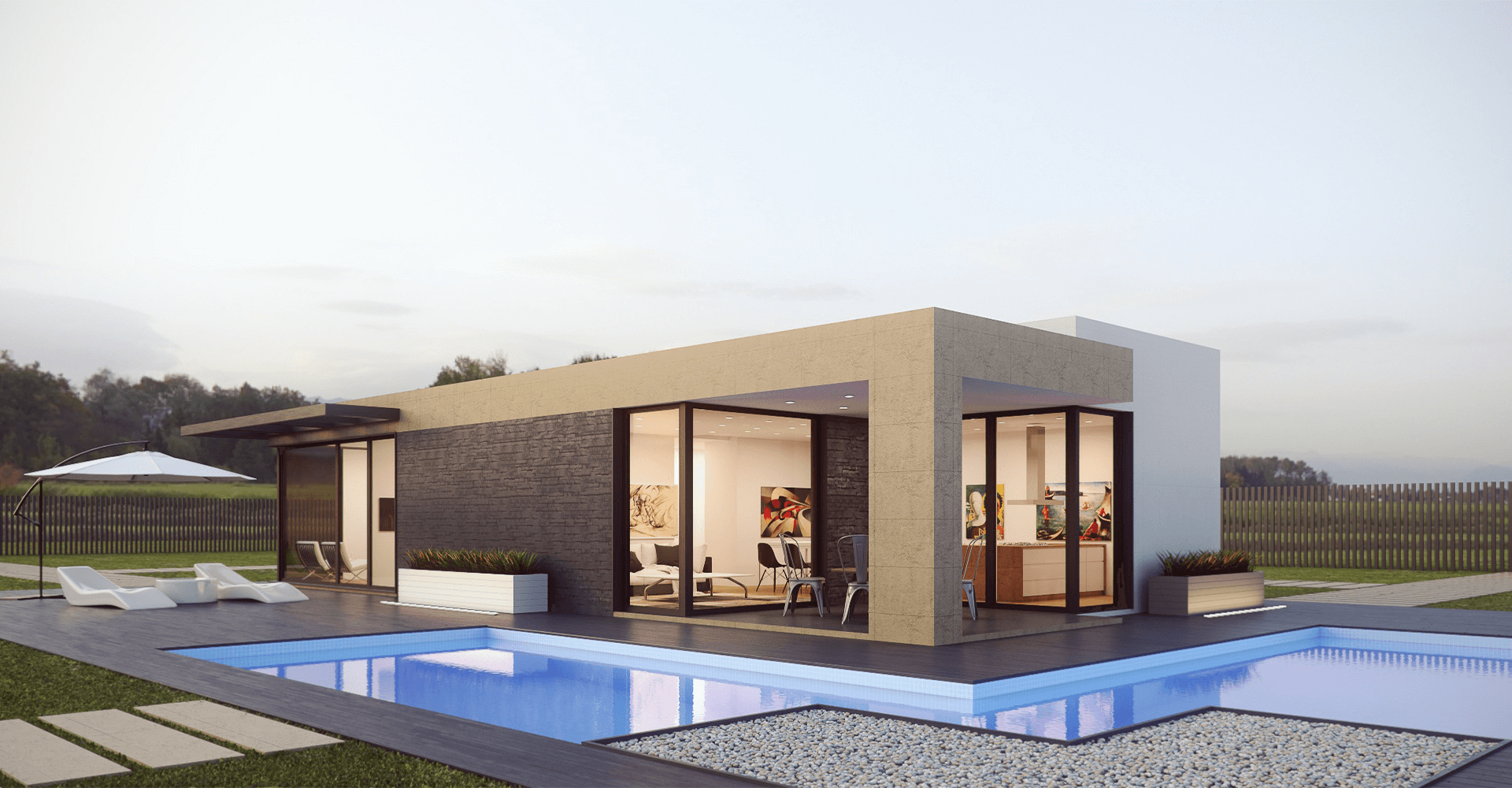

Speed - Delivered in 6-8 weeks and installed within 48 hours.

Credentials - NHBC Warranty, Insurable & Mortgage able.

Cheaper - From 25% cheaper in controlled manufacturing environments.

Assurance - Experienced Management Team in partnership with blue-chip partners.

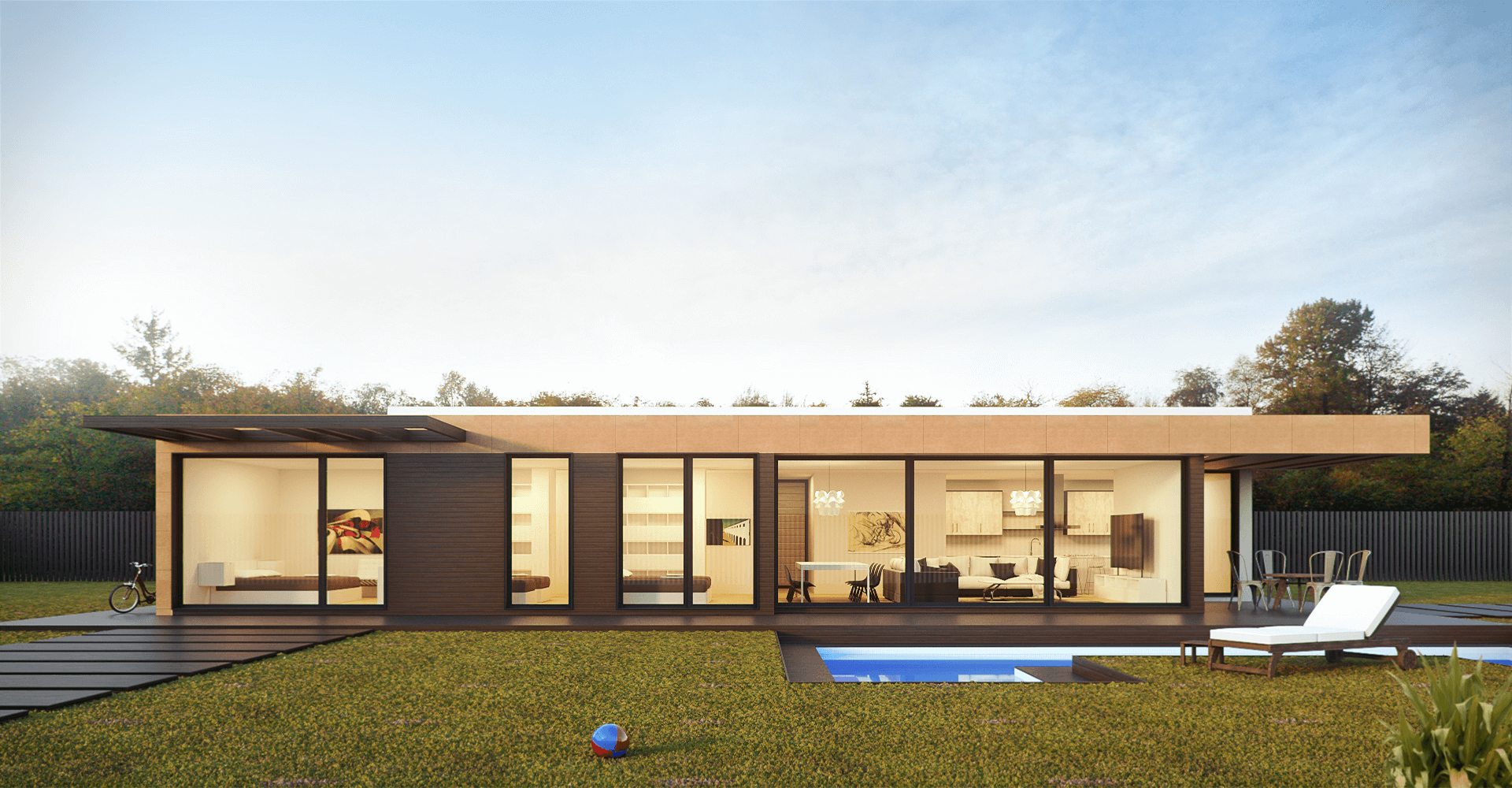

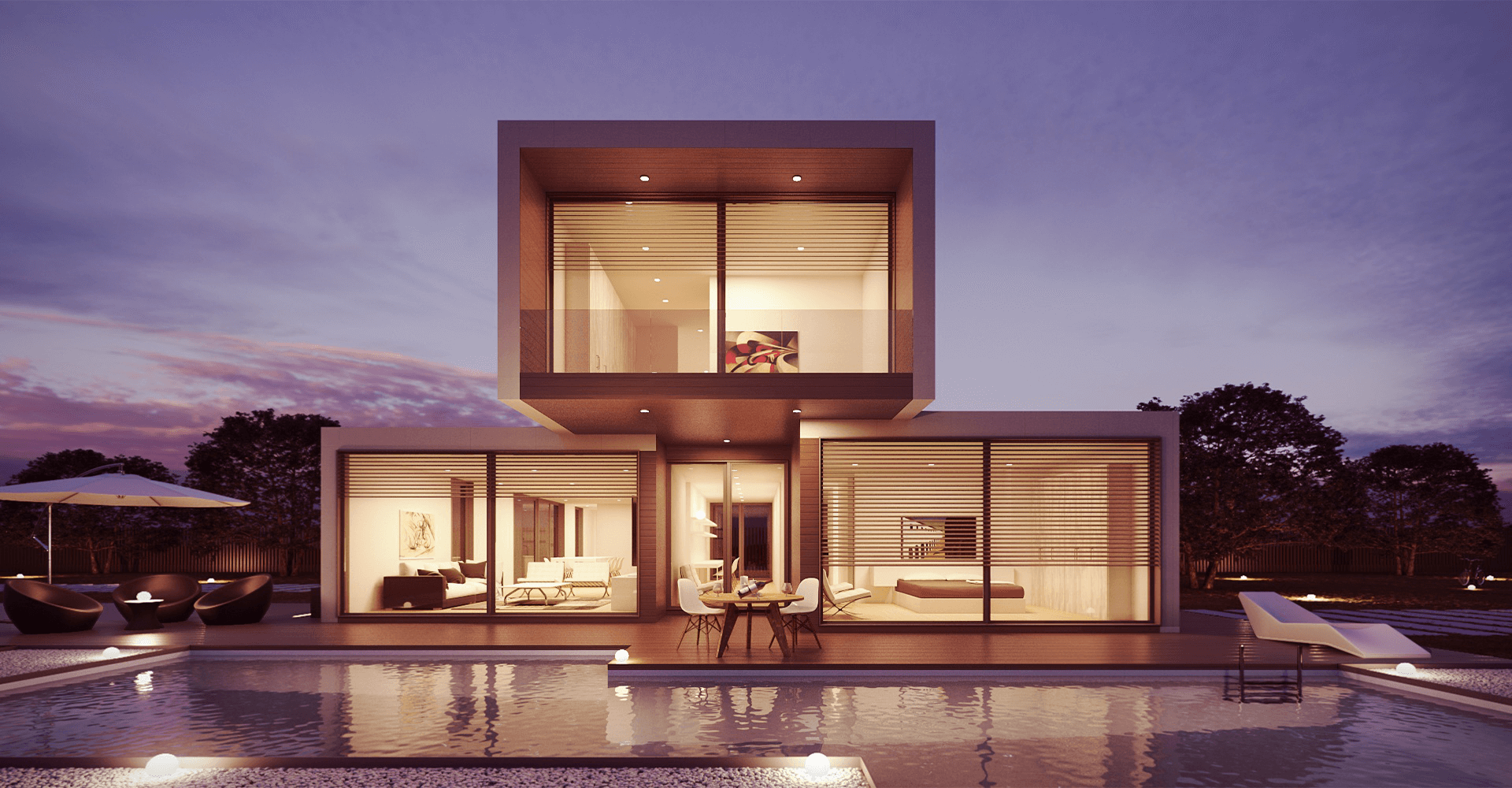

Modules are our speciality.

Modules are our speciality. The idea of ??modular technology is to perform almost all works not on the construction site where uncomfortable climatic conditions prevail, but in a warm hall on modern, computer-controlled production machines.

The place of production can be distanced from the construction site even by thousands of kilometres. The apartments produced by us are finished and ready to be assembled after assembly.

The modules have different dimensions depending on the design possibilities, the needs of a specific project and transport conditions. A single module can create an independent small apartment or be part of a larger apartment. One flat can consist of 1, 2 or even 3 modules, which allows you to design apartments with an area of up to 150m 2 containing rooms extending over more than one module. In turn, in buildings such as hotels or dormitories, you can place up to two closed rooms with a bathroom within one module. The assembly takes place using the "Lego bricks" method, in a few days the modules form a multi-family building with several dozen flats. Most often, 2-4 floor buildings are designed, which are the most economically efficient, but modular technology allows buildings of up to 6-7 floors to be erected.

Modular building options.

Apartments.

Care Homes.

Commercial.

Education.

Emergency Housing.

Hotels.

Housing.

Sports/Events.

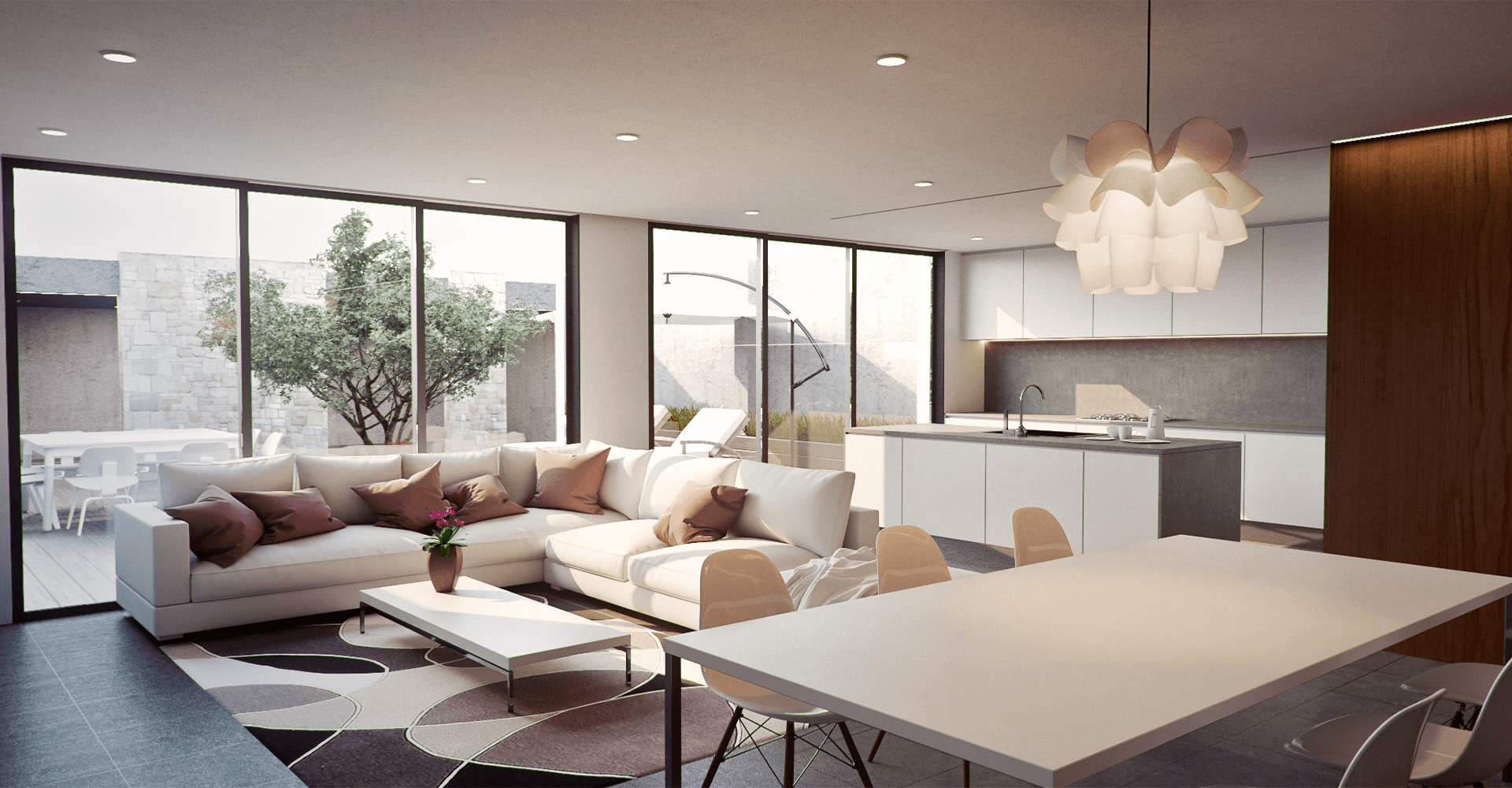

Work done in modules at the factory.

We finish walls, ceilings and floors (plaster, paint, glaze, terracotta, floor board).

We install installations (sanitary, electric, ventilation, sprinkler).

We install household appliances in the kitchen (fridge, dishwasher, oven and hob).

We put in doors and windows.

We put in kitchen furniture and a wardrobe.

We put a white assembly in the bathroom (toilet, shower, sink).

We install mechanical ventilation and fire sprinklers.

We arrange lighting, switches and sockets.

We install heating (floor, water).

We cover the external surfaces of the walls (plaster, scale, stone and slab).

Works carried out on the construction site.

We assemble the modules by connecting them to the target shape of the building.

We are finishing connections between modules.

We combine installations in individual modules into one network.

We assemble finished external elements such as fire stairs, balconies and galleries.

Modular houses are significantly cheaper to maintain compared to masonry buildings of the same area - thanks to the excellent parameters of the materials used (e.g. very low heat transfer coefficient of wool filled skeletal walls) and ecological solutions (e.g. mechanical ventilation with heat recovery).