What is Modular Construction?

Modular construction is a process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities – but in about half the time. Buildings are produced in “modules” that when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.

View this short video to learn more.

GREENER.

The factory-controlled process generates less waste, creates fewer site disturbances and allows for tighter construction.

FASTER.

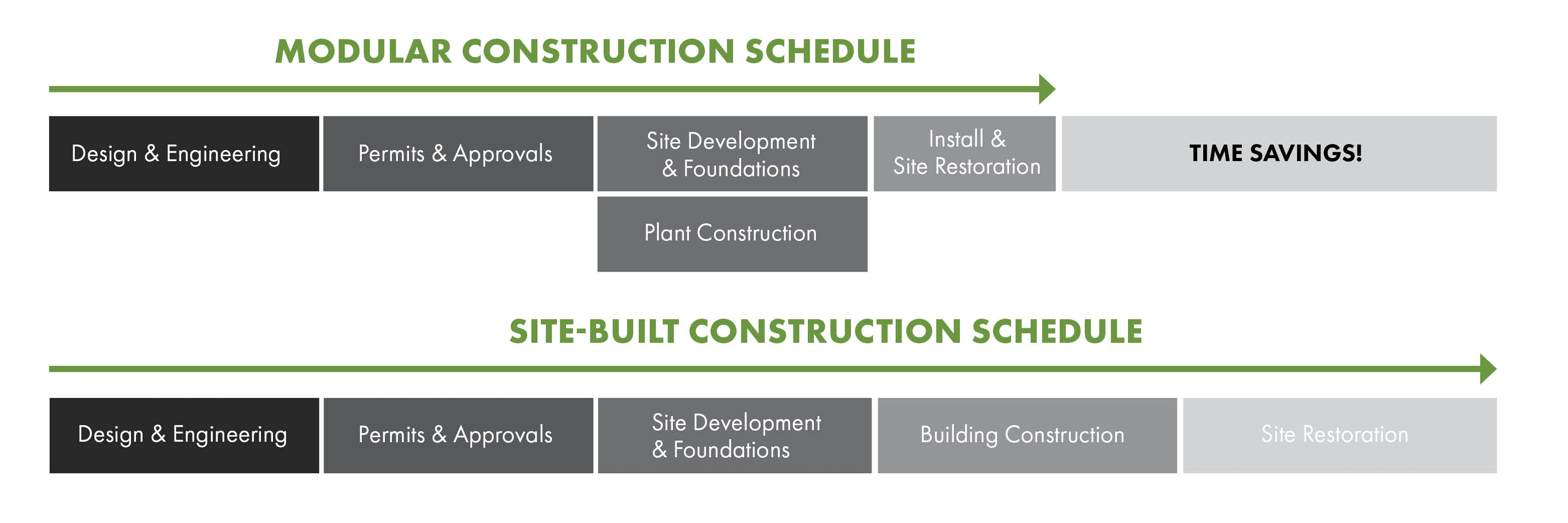

Construction of modular buildings occurs simultaneously with site work, allowing projects to be completed in half the time of traditional construction.

SMARTER.

Modular buildings are built with the same materials and to the same building codes and architectural specifications as traditional construction. Once assembled, they are virtually indistinguishable from their site-built counterparts.

Greater Flexibility and Reuse:

Modular buildings can be disassembled and the modules relocated or refurbished for new use, reducing the demand for raw materials and minimizing the amount of energy expended to create a building to meet the new need.

Reduced Construction Schedule:

Because construction of modular buildings can occur simultaneously with the site and foundation work, projects can be completed 30% to 50% sooner than traditional construction.

Safer Construction:

The indoor construction environment reduces the risks of accidents and related liabilities for workers.

Less Material Waste:

When building in a factory, waste is eliminated by recycling materials, controlling inventory and protecting building materials.

Elimination of Weather Delays:

60 - 90% of the construction is completed inside a factory, which mitigates the risk of weather delays. Buildings are occupied sooner, creating a faster return on investment.

Better Engineered Building & BIM:

PMC relies on advanced BIM for visualization to assess the energy performance and identify the most cost-effective efficiency measures. PMC is ideal for the use of this technology where the construction process is already a collaboration of systems, materials and people—much like the software itself.

Improved Air Quality:

Because the modular structure is substantially completed in a factory-controlled setting using dry materials, the potential for high levels of moisture being trapped in the new construction is eliminated.

Built to Code with Quality Materials:

Modular buildings are built to meet or exceed the same building codes and standards as site-built structures, and the same architect-specified materials used in conventionally constructed buildings are used in modular construction projects – wood, concrete and steel.

Limitless Design Opportunities:

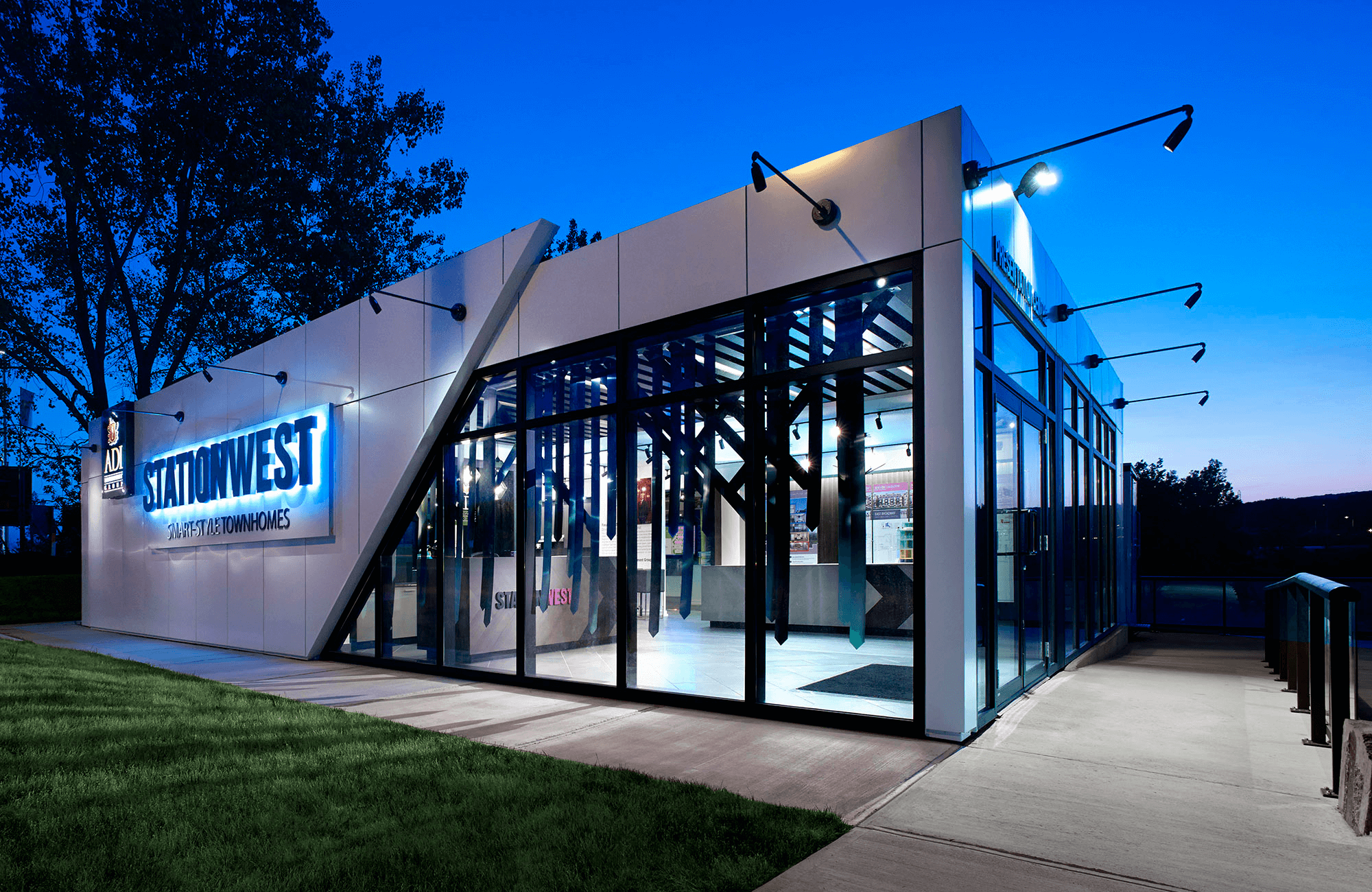

Modular units may be designed to fit in with external aesthetics of any existing building and modular units, once assembled, are virtually indistinguishable from their site-built counterparts.

Why Not Build Modular?

Structurally, modular buildings are generally stronger than site-built construction because each module is engineered to independently withstand the rigors of transportation and craning onto foundations. Once together and sealed, the modules become one integrated wall, floor, and roof assembly. Building offsite ensures better construction quality management. Manufacturing plants have stringent QA/QC programs with independent inspection and testing protocols that promote superior quality of construction every step of the way.

Beyond quality management and improved completion time, modular construction offers numerous other benefits to owners. Removing approximately 80% of the building construction activity from the site location significantly reduces site disruption, vehicular traffic, and improves overall safety and security. Highly active businesses such as those in the education and healthcare markets have need for reduced on-site activity and offsite construction eliminates a large part of ongoing construction hazards, ensuring a tremendous advantage when building new projects.

For architects, developers, and owners alike, modular construction companies today can work with levels of design and construction sophistication that will exceed all expectations, rivaling their site-built counterparts. It is beneficial that when exploring the various project delivery methods, offsite construction is chosen early in the design development process, and the project built around that methodology, to avoid redesigning. Most modular companies, however, can take a site-built design and create a modular version when required, so it’s never too late to explore the possibilities!

As owners and designers look for more sustainable designs for improved environmental impact, modular construction is inherently a natural fit. Building in a controlled environment reduces waste through avoidance upstream rather than diversion downstream. This, along with improved quality management throughout the construction process and significantly less on-site activity and disturbance, inherently promotes sustainability. High quality, sustainable, innovative, efficient, cost-effective, and shorter time to completion.

Two Types of Modular Construction.

Permanent Modular Construction.

Permanent Modular Construction (PMC) is an innovative, sustainable construction delivery method utilizing offsite, lean manufacturing techniques to prefabricate single or multi-story whole building solutions in deliverable module sections. PMC modules can be integrated into site built projects or stand alone as a turn-key solution and can be delivered with MEP, fixtures and interior finishes in less time -- with less waste, and higher quality control compared to projects utilizing only site-built construction. Recent research has come out supporting the fact that modular construction is an efficient construction process and poised to help the construction industry grow.

Relocatable Buildings.

A Relocatable Building (RB) is a partially or completely assembled building that complies with applicable codes or state regulations and is constructed in a building manufacturing facility using a modular construction process. Relocatable buildings are designed to be reused or repurposed multiple times and transported to different building sites. They are utilized for schools, construction site offices, medical clinics, sales centers, and in any application where a relocatable building can meet a temporary space need. These buildings offer fast delivery, ease of relocation, low-cost reconfiguration, accelerated depreciation schedules and enormous flexibility. Relocatable buildings are not permanently affixed to real estate but are installed in accordance with manufacturer’s installation guidelines and local code requirements. These buildings are essential in cases where speed, temporary space, and the ability to relocate are necessary.

“Manufacturing building components off-site provides for more controlled conditions and allows for improved quality and precision in the fabrication of the component.” - National Institute of Standards and Technology and the National Research Council.